WHO WE ARE

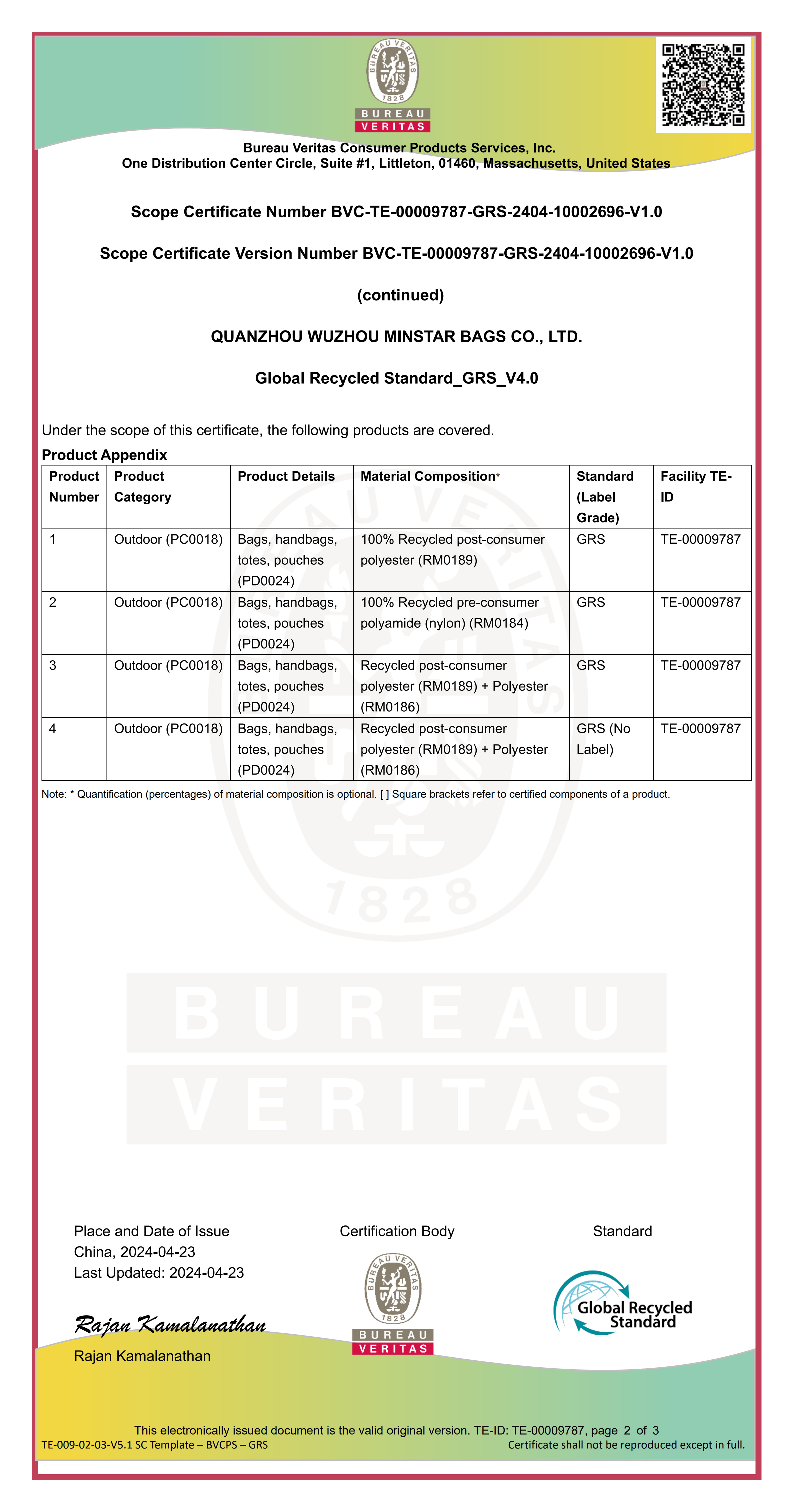

As a premier OEM factory certified by BSCI and GRS, we pride ourselves on our extensive expertise in manufacturing a diverse array of bags, including backpacks, laptop bags, school bags, diaper bags, sports bags, outdoor bags, travel bags, and trolley bags. Our products are not only crafted with the utmost attention to detail but also offered at highly competitive prices, ensuring that customers receive the best value without compromising on quality.

We provide both ODM and OEM services, allowing us to tailor our products to meet the unique needs of our international customers and trade distributors. Our commitment to fostering long-term, mutually beneficial relationships has been a cornerstone of our success. With a broad and versatile product portfolio, a strong reputation for reliability, and a loyal customer base, we are poised to further strengthen our position in the global market. As we continue to expand our operations and refine our processes, we strive to become a dominant force in the bag manufacturing industry, setting new standards for innovation, quality, and customer satisfaction.